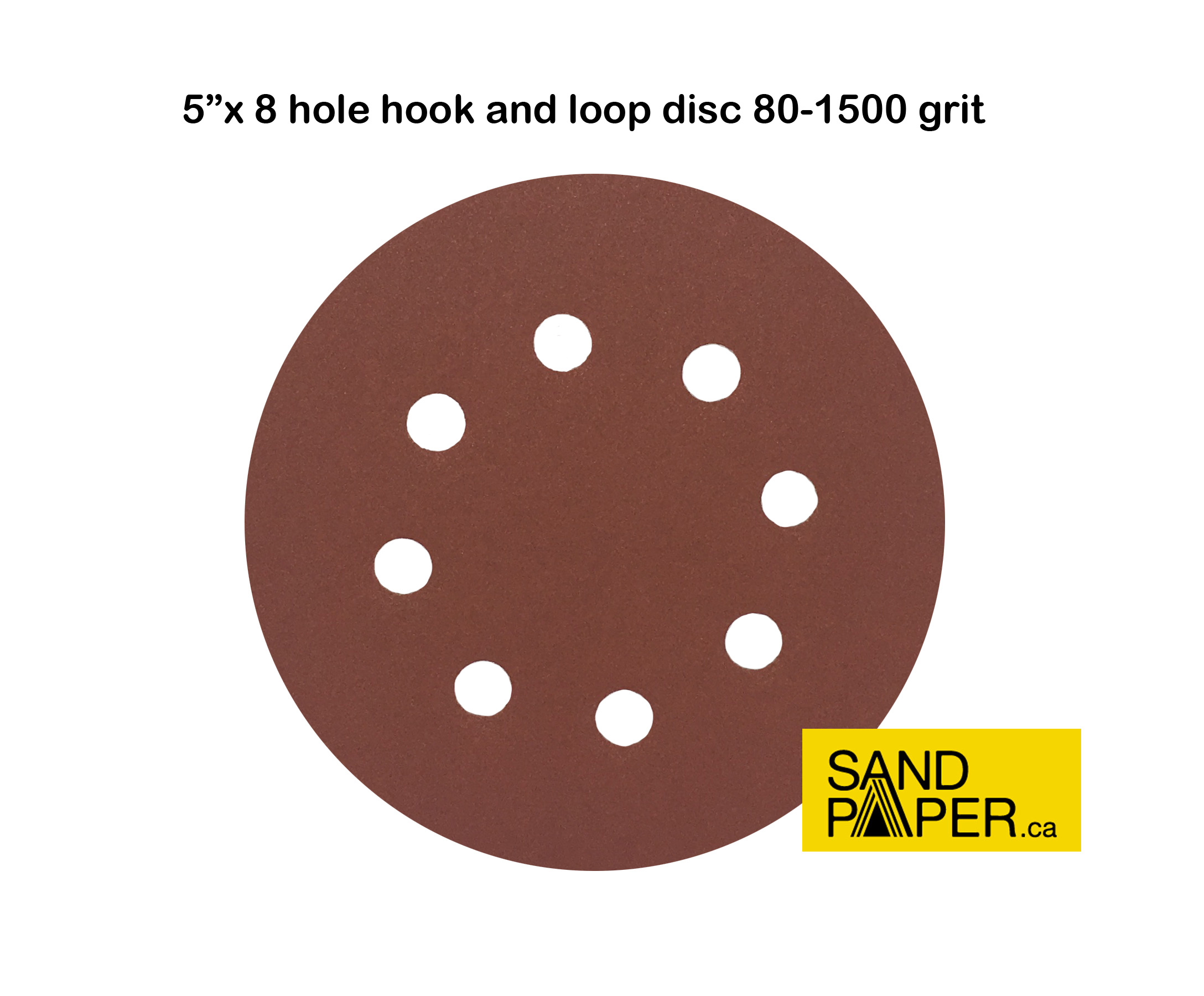

You are probably familiar with Velcro, whether from clothing or shoes or so many other places where it shows up to provide that strong attachment. The invention of Velcro was introduced to sandpapers, replacing the self-adhesive of a PSA pad sandpaper for an even easier attachment to power tools. Hook and loop sandpaper attaches differently. PSA sandpaper comes in all grits, and with a peel-off back to expose the adhesive, simply attach with a bit of pressure to the power tool of your choice. Pressure sensitive adhesive pretty much says it all. What’s the Difference Between PSA Pad Sandpaper and Hook-and-Loop sandpaper? PSA pads (Pressure Sensitive Adhesive) were followed by hook and loop sandpaper.

As power sanders became ubiquitous, so did the sandpapers that could be used with them.

0 kommentar(er)

0 kommentar(er)